tel: 408.320.4972

Services:

Instant quotes

● Send a 3D CAD file, Dimensions and address

● Get a plug or pattern quote

● Get your part delivered

Technologies

● 3D Scanning

● CNC router 3, 4 and 5 Axis

● CNC HotWire 2 and 4 Axis

Materials

● EPS foam 1LB

● EPS foam 2LB

● Urethane tooling foam 5-30LB

● Tooling board

Useable file formats:

● DXF

● VRML

● STEP

● STL

● IGES

● 3DM

Examples:

● 2,3,4 and 6 wheel Vehicles

● Aircraft

● Boats

● Surfboards and Windsurf Boards

● Canoes (Hawaiian Outrigger)

● Furniture, Kiosk, POP

● Custom Packaging

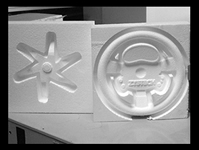

● Proof of Concepts

● Tubs and Planters

GET QUOTE

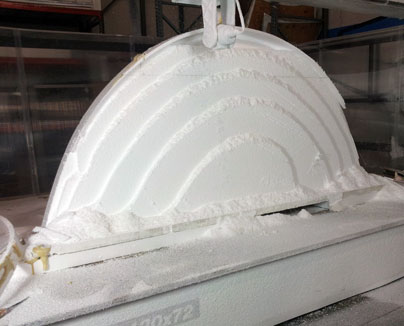

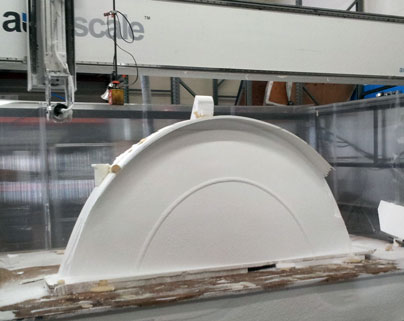

The finishing begins

After any part is machined from either EPS or tooling foam it must be sealed and primmer. This can be time consuming and is very important. The finished surface will reflect what the final part will look like. This is the final step prior to building the mold.

• CAM ( Computer Aided Machining )

• CNC ( Computer Numerical Control )

• Epoxy Resin vs. Polyester Resin

In any high-tech structural application, where strength, stiffness,

durability and light weight are required, epoxy resins are seen as the

minimum standard of performance for the matrix of the composite.

This is why in aircraft and aerospace applications, as well as

offshore racing boats, epoxies have been the norm for years.

However 95% of pleasure boats under 60 feet today are still made

with polyester resin. The main consideration for materials selection

for most composite builders is cost, with performance and more

importantly value for money often being a secondary consideration.

As a general rule epoxy resins are twice as expensive as vinyl ester

resins and vinyl ester resins are twice as expensive as polyesters.

Since the resin can constitute 40 to 50% of the weight of a

composite component, this price difference is seen as having a

significant impact on the cost of the laminate.

However, when considered against the cost of the whole structure

(the car) the cost is relatively insignificant, and the value of higher

quality and long term gain of better durability (therefore better resale

value) can be tremendous.

What contributes to this better value…..?

Epoxy resins have performance advantages over polyester and vinyl

esters in four major areas:

• Better adhesive properties (the ability to bond to the

reinforcement or core)

• Molding tolerances (Very little shrinkage)

• Superior mechanical properties (particularly strength and

stiffness)

• Improved resistance to fatigue and micro cracking